According to its properties its application and usages will be vary. This video introduces and explains the differences between ductile and brittle materials for A Level PhysicsA short video that explain the various material.

Ductility Definition Examples Video Lesson Transcript Study Com

The brittle material is glass Plain concrete cast iron etc.

Is tin material brittle or ductile. Understanding of fracture behavior is useful in selecting materials for product designs and it is incredibly valuable to know if a material will experience a ductile-brittle transition and what temperature this transition occurs. What is the difference between ductile and brittle materials. The main difference between ductile and brittle materials is that ductile materials are able to be drawn out into thin wires whereas brittle materials are hard but liable to break easily.

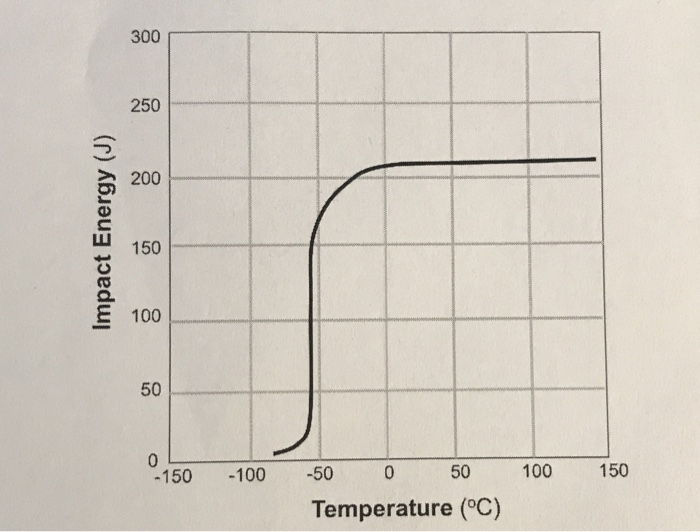

Which metal is brittle in nature. Investigations are performed in an erosion test rig where the ductile and brittle materials are charged with spherical and angular SiO2 particles at normal impact. The minimum temperature at which the metal transitions from a brittle behavior to a ductile behavior or from a ductile behavior to a brittle behavior is known as the ductile-brittle transition temperature DBTT.

The tensile test of metal components can be an indicator for the observation of the fracture types. Answer 1 of 5. Brittle and Ductile are the two important material properties belongs to the strength of materials subject that are used to describe the physical and chemical properties of materials.

Why is the brittle material not so useful even though it may have a high strength. Most of the metals are ductile because the dislocations can ea. Such a condition is the effect of temperature.

During the tensile testing of metals curved edges at the necking point of the. By varying composition we can make brass some what brittle. Ductile materials frequently undergo brittle fracture.

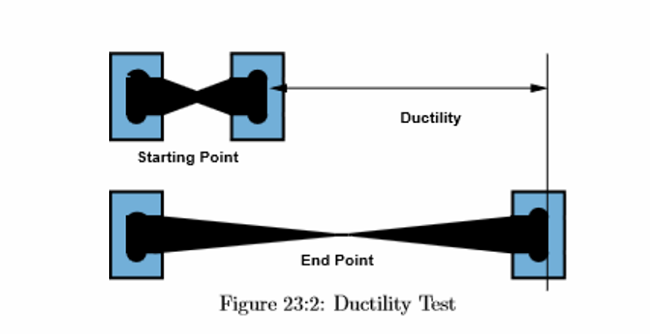

What Are Brittle and Ductile Meant. The term brittleness is the process of acquiring the brittle property by any material. Ductility is a physical property of a material that is associated with the ability to be hammered thin or stretched into wire without breaking.

Quick brittle a property applicable to a material if fracture occurs soon after the elastic limit is passed ductile a property applicable to a material if a large amount of plastic deformation takes place between the elastic limit and the fracture point ductility the ability of a material to be permanently deformed without breaking when the applied load is removed. Ductile to Brittle Transition. A naturally malleable metal can be made stronger by impeding the mechanisms of plastic deformation reducing grain size precipitation hardening work hardening etc but if this is taken to an extreme fracture becomes the more likely outcome and the material can become brittle.

Brittle material absorbs little energy prior to rapture. But its properties depends on the composition of Zinc and copper. The present work discusses the influence of erodent shape on the wear behavior of a ductile Ti-6Al-4 V alloy and a brittle TiN coating material during the erosion process.

When a material has reached the limit of its strength it usually has the option of either deformation or fracture. The transition temperature of high purity Sn Sn-05Cu and Sn-05CuNi alloys is around -125C. A ductile to brittle fracture transition was found for them ie.

The ductile materials are Steel Aluminum copper etc. Steel is the most commonly used metal that shows this behaviour. The factors that cause these different behaviors include.

Strength Strength is the most. Brittle materials fail by sudden fracture without any warning such as necking. The proportions of zinc and copper can be varied to.

Energy absorbed by ductile materials before fracture under tensile testing is more. Elongation and reduction of area as well as notch toughness impact test and hardness testing can give a quantitative value to ductility by measuring the amount of energy the material absorbs and converts to mechanical deformation. Brittle materials break without significant plastic deformation under tensile stress.

Inherently brittle materials rarely crack in a ductile mode. Materials that usually fracture in a brittle manner are glasses ceramics and some polymers and metals. The temperature where the material changes from brittle to ductile or vice versa is crucial for the design of load-bearing metallic products.

A material is brittle if when subjected to stress it fractures with little elastic deformation and without significant plastic deformation. Generally for each material there is such a critical temperature. Materials can be named as ductile materials or brittle materials based on their response to an applied stress on them.

Various metal forming operations such as rolling forging drawing bending etc can be performed on ductile materials. Brittle materials absorb very small energy before fracture. The materials having this property are known as ductile materials.

The ductile material commonly used in engineering practice in order of diminishing ductility are mild steel copper aluminium nickel zinc and tin. Brittle materials ceramics concrete untempered steel are stronger higher tensile strength -yield point and uts and harder than ductile as they do not undergo significant plastic elongation deformation and fail by breaking of the bonds between atoms which requires a tensile stress along the bond. The ductile to brittle transition temperature is strongly dependant on the composition of the metal.

To have either a ductile or brittle metal defines the failure mechanism which you can tell by having either a ductile fracture or a brittle fracture. Hence the required energy for a ductile fracture is higher than the need for a brittle fracture. Generally brass is ductile in nature.

Normally if the percentage elongation exceeds 5 the material is ductile and if it is less than 5 the material is brittle. Knowledge of a materials ductile-brittle transition temperature can prevent catastrophes such as the WW2 Liberty Ship failure. A ductile material can easily be drawn into.

A brittle metal may behave in a ductile manner. This is known as a ductile to brittle transition. Brittle materials absorb relatively little energy prior to fracture even those of high strength.

The main difference between ductile and brittle materials is that ductile materials are able to be drawn out into thin wires whereas brittle materials are hard but liable to. Ductile materials under some conditions can become brittle if the conditions are changed. Ductile brittle transition temperature At low temperature the material makes the metal brittle because of the weakening of free electron activity and adhesion around its atoms.

Under some circumstances some metals that are usually ductile will fail in a brittle manner possibly with catastrophic results. Gold Platinum Silver Copper Aluminium Nickel Zinc Tin. Many materials of industrial use exhibit ductile fracture at ambient and elevated temperatures and brittle fracture at low temperatures.

Also called sudden failure. At low temperatures some metals that would be ductile at room temperature become brittle. Is Brass a ductile or brittle material.

When the ambient temperature is lower than the critical temperature the impact toughness of. Like ductile fractures brittle fractures also have a distinctive fracture surface. How can you classify objects that are brittle.

Strength temperature rate of loading stress concentrations size and various combinations. The ductile fracture process comes with massive energy absorption. The mobility of dislocations during deformation determines whether a material is ductile or brittle The key point in deforming a material is the understanding of interactions between dislocations during their motion.

A sharp change in their fracture toughness compared to no transition for the eutectic Sn-Pb. Brittle Deformation Ductile Ductility Metal Metallic Bond.

Solved The Plot Below Shows The Ductile To Brittle Chegg Com

Malleability And Ductility Matse 81 Materials In Today S World

Brittle Transition Temperature An Overview Sciencedirect Topics

Ductile Fracture And Brittle Fracture An Overview Sciencedirect Topics

Why Do Some Metals Become Brittle At Low Temperatures

Tidak ada komentar