Risk assessment is the process of evaluation of the risks arising from a hazard taking into account the adequacy of any existing controls and deciding whether or not the risks is acceptable. 2 Assessing exposure risk Any mining or exploration company whose operations have the potential to disturb mine concentrate process or handle toxic materials or use hazardous chemicals must identify assess and monitor employees exposures and the effects of these hazards.

The Exploration Process Evolution Mining

For this reason the prevalence and severity of occupational diseases in the mining industry depends on the ores mined the contaminants present and also on the levels and duration of exposure and coexisting illnesses in the exposed population and their environmental conditions and lifestyles.

Chemicals risk assessment for tin mining processing. Occupational Health and Safety Act 2000 refer Sections 7 8. Action plan for handling safety system to be incorporated. ZDHC CMS 242 - Environmental ProcessPlan for reducing Environmental Impact.

They may have health hazards physical hazards or both. The risk assessment follows the methodology outlined in Australian Standard AS 43601999. Identify if and what kind of control measures should be implemented and.

If these values change significantly then a new matrix may be warranted. Shizhuns multi-disciplinary experts team provides process safety and risk assessment services by combining professional technical knowledge advanced risk management theory applicable simulation software and process safety helps owners and contractors identify assess and manage risks that may occur during design construction and operation at different stages of the project to ensure the. A Job.

Dose-response determination LD50LC50 NOAEL T25 EC50 NOEC etc determining the relationship between the magnitude of exposure to a hazard and the probability and severity of adverse effects. The risk of chemicals in the gray and black zones must be reduced. The trace metal concentrations in edible muscle of red tilapia Oreochromis spp sampled from a former tin mining pool concrete tank and earthen pond in Jelebu were analysed with microwave assisted digestion-inductively coupled plasma-mass spectrometry.

Subscribe to information about. Hazardous chemicals such as sulphur dioxide hydrogen sulphide carbon monoxide and oxides of nitrogen may be generated during the processing of mineral ores. Documents on the risk assessment of chemicals.

Concise International Chemical Assessment Document 65 TIN AND INORGANIC TIN COMPOUNDS. - Risk is the combination of the severity of hazard and probability of the occurrence of the incident. This guide outlines some of the common health and safety risks of storing chemicals and shows you ways to manage those risks it includes a storage checklist that sets out the standard precautions everyone should take and a detailed chart that.

Is a specialist consultancy dedicated to responsible mining and sourcing. ZDHC 243 - Health and Safety ProcessPlan for reducing Environmental Impact. Sodium cyanide is strictly managed to minimise worker exposure through direct contact or from hydrogen cyanide gas.

Of control of chemical processes or the significant loss of containment of chemicals in storage or transport. Identify which workers are at risk of exposure to COVID-19. Process for reducing Health and Safety Impacts such as Action Plans.

A black unacceptable high risk zone MPL. International Chemical Safety Cards on the relevant chemicals are attached at the end of the CICAD to. This is why plants make use of Risk Assessment Forms to identify and lessen if not eliminate the risks present in a plant.

RISK ASSESSMENT AND PREVENTATIVE MEASURES 31 TERRESTRIAL ENVIRONMENT The residual risks posed by hydrocarbon and chemical storage and use at the port are outlined in Table 3. And a white low risk level. Results were compared with established legal.

Risk assessments will help mine operators to identify high medium and low risk levels. It does not cover the management of risks from the physical. 2 Moreover the unclaimed ore and spent processing chemicals known as tailings 34 are discharged.

Manufacturing and industrial plants can be hazardous due to the use of various hazardous chemicals and heavy machinery. The risk assessment process tool. Australian Work Health and Safety Strategy Chemical exposure standards Data and research Disease injury and behavioural issues Hazardous chemicals Hazards and safety issues Multimedia resources National Safe Work Month Occupational Lung Diseases Psychosocial mental health QuadWatch Safe Work Australia News Training licensing competencies.

It may also be defined as a percentage of MPL for instance 1 or 10 of MPL. Examples of chemicals that can cause adverse health effects include. Working from concept to implementation in all cases we help our clients transform their ideas.

It is impossible to eliminate all hazards so the goal is to eliminate andor control the hazards with critical and high potential risk to the lowest reasonable risk level so as to protect workers from harm. Hazard and Risk Assessment Inventory. The Mines Safety and Inspection Regulations 1995 require a workplace to undertake risk assessments to determine the consequences of exposure to hazardous agents chemicals or other substances that may affect the health of workers.

WHY DO RISK ASSESSMENTS. 3T Tin tantalum and tungsten 3TG Tin tantalum tungsten and gold. Risk assessments will help the mine operators to identify high medium and low risk levels.

In general chemical risk assessment consists of the following three steps. Conducting the risk assessment. The process of Risk Assessment has to be very thorough because the consequences could be dire if anything is missed.

Bulk hydrocarbon diesel storage is expected to be limited to. Risk assessments will help to prioritise risks and provide information on the probability of harm arising and severity of harm by understanding the hazard combine assessments of probability and severity to produce an assessment of risk and it is used in. Mineral Supply Chain Due Diligence Audits and Risk Assessments in the Great Lakes Region.

The two risk limits create three zones. A gray medium risk level. Hazardous chemicals are substances mixtures and articles that can pose a significant risk to health and safety if not managed correctly.

Risk assessment for storage and handling of hazardous chemicalssolvents. JSA with PPE for Chemical HandlingExposure. Determine what sources and processes are causing the risk.

In general the same matrix should be used for successive operations at a given project or well to provide continuity so long as the relative values remain repre-sentative of the project or well over time. Risk assessment is the process of. A risk assessment will also assist your employer to.

Risk assessments will help to prioritise the risks and provide information on. Check the effectiveness of existing control measures. This is a requirement of the.

A Review On The Impact Of Mining Operation Monitoring Assessment And Management Sciencedirect

Pdf Morphology Geology And Water Quality Assessment Of Former Tin Mining Catchment

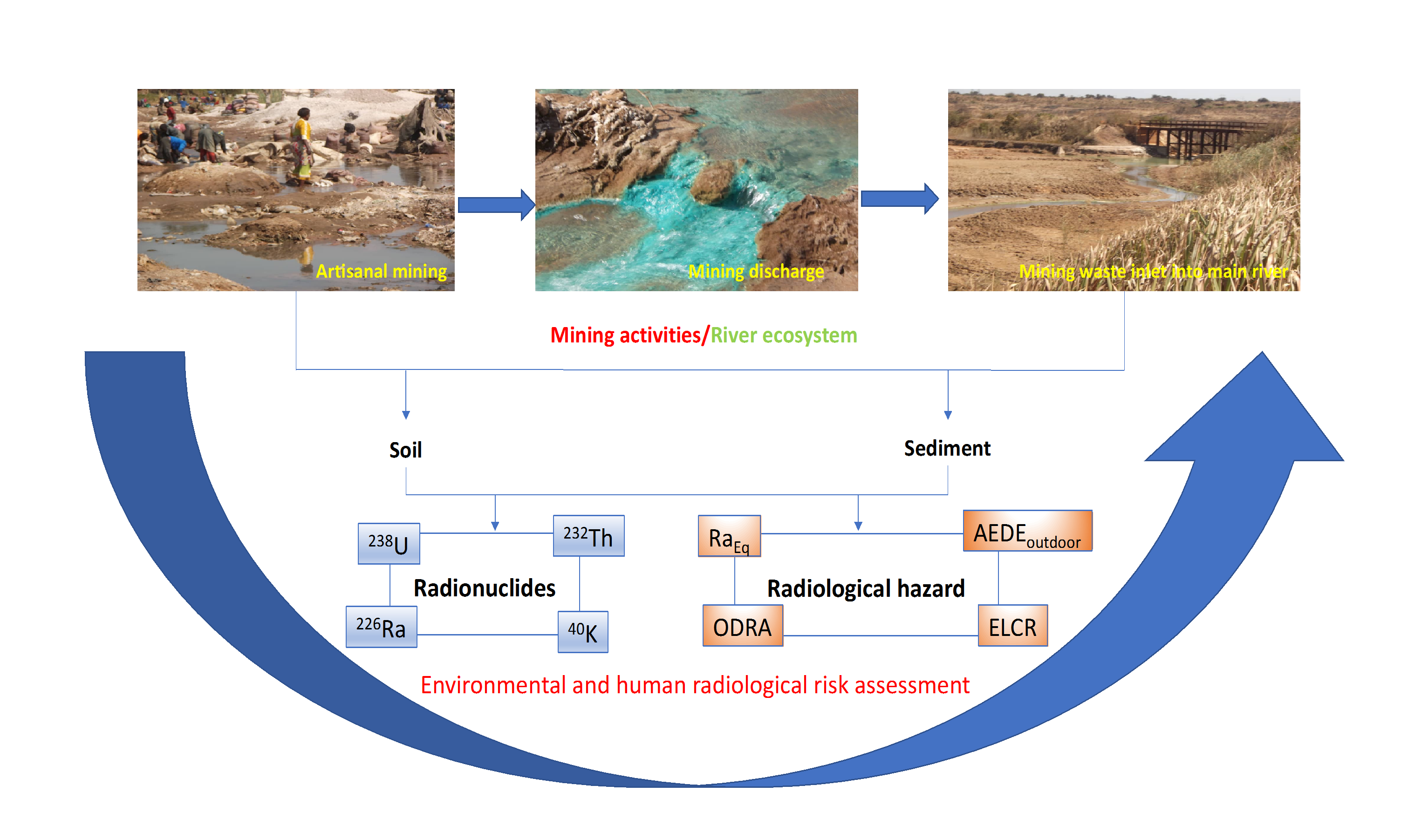

Assessment Of Natural Radioactivity In Rivers Sediment And Soil From The Copper Belt Artisanal Mining Region Democratic Republic Of The Congo

Hazardous Minerals Mining Challenges And Solutions Sciencedirect

Tidak ada komentar