Fluorine doped tin oxide. A mixture comprising 03 g of one of the FCS and 3 g SnO 2 was premixed manually in an agate mortar and co-milled at 800 rpm for 1 h.

Influence Of Preferred Orientation On The Electrical Conductivity Of Fluorine Doped Tin Oxide Films Scientific Reports

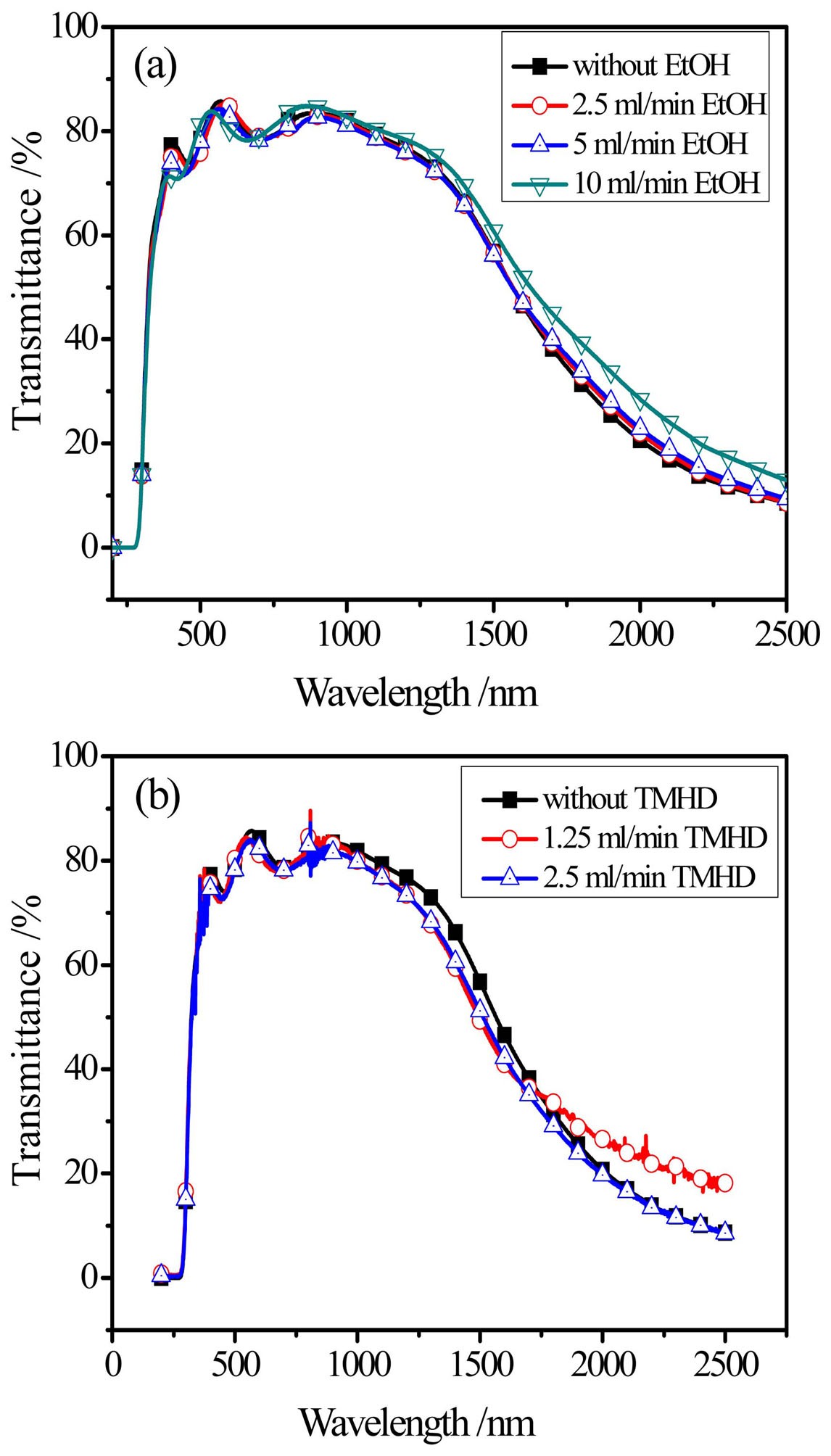

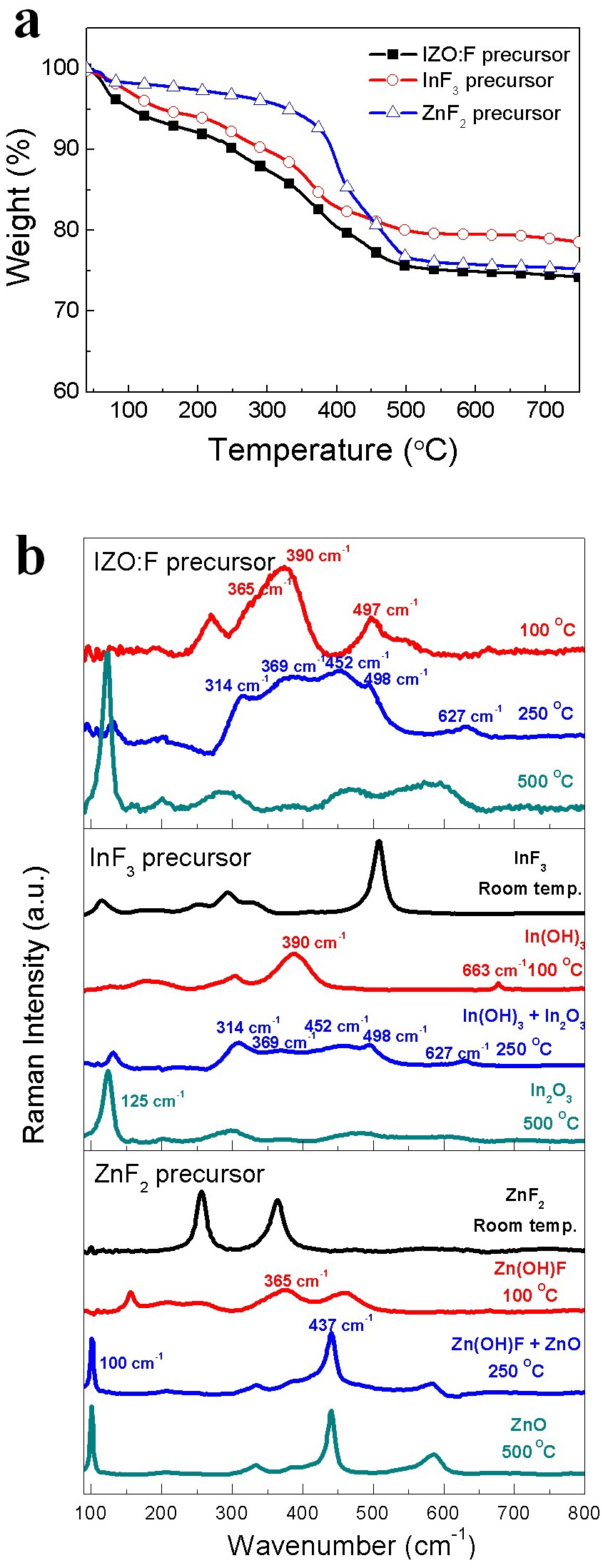

Figure 1 displays the thermogravimetric analysis TGA results of aqueous metal fluoride solutions measured under dry air atmosphere.

Fluorine tin oxide decomposition. Metal oxide fume Hydrogen fluoride. Fluorine Doped Tin Oxide FTO sputtering targets are composed of ceramic optical glass and are electrically conductive color-neutral and flexible. An improved liquid coating composition for producing high quality high performance fluorine-doped tin oxide coatings by chemical vapor deposition includes the reaction product of a reactive fluorine dopant compound and an organotin compound preferably 1-30 wt.

Results were compared with respect to samples grown using a common fluorine source NH. Corrosive solid acidic inorganic nos. We report in this paper a new atmospheric pressure CVD process for producing fluorine-doped zinc oxide which has the potential to make this high-performance TCO at low cost.

About Fluorine Doped Tin Oxide FTO Sputtering Target. SnO 2 cassiterite Aldrich 325 mesh was chosen as a starting tin oxide. It is a colourless diamagnetic amphoteric solid.

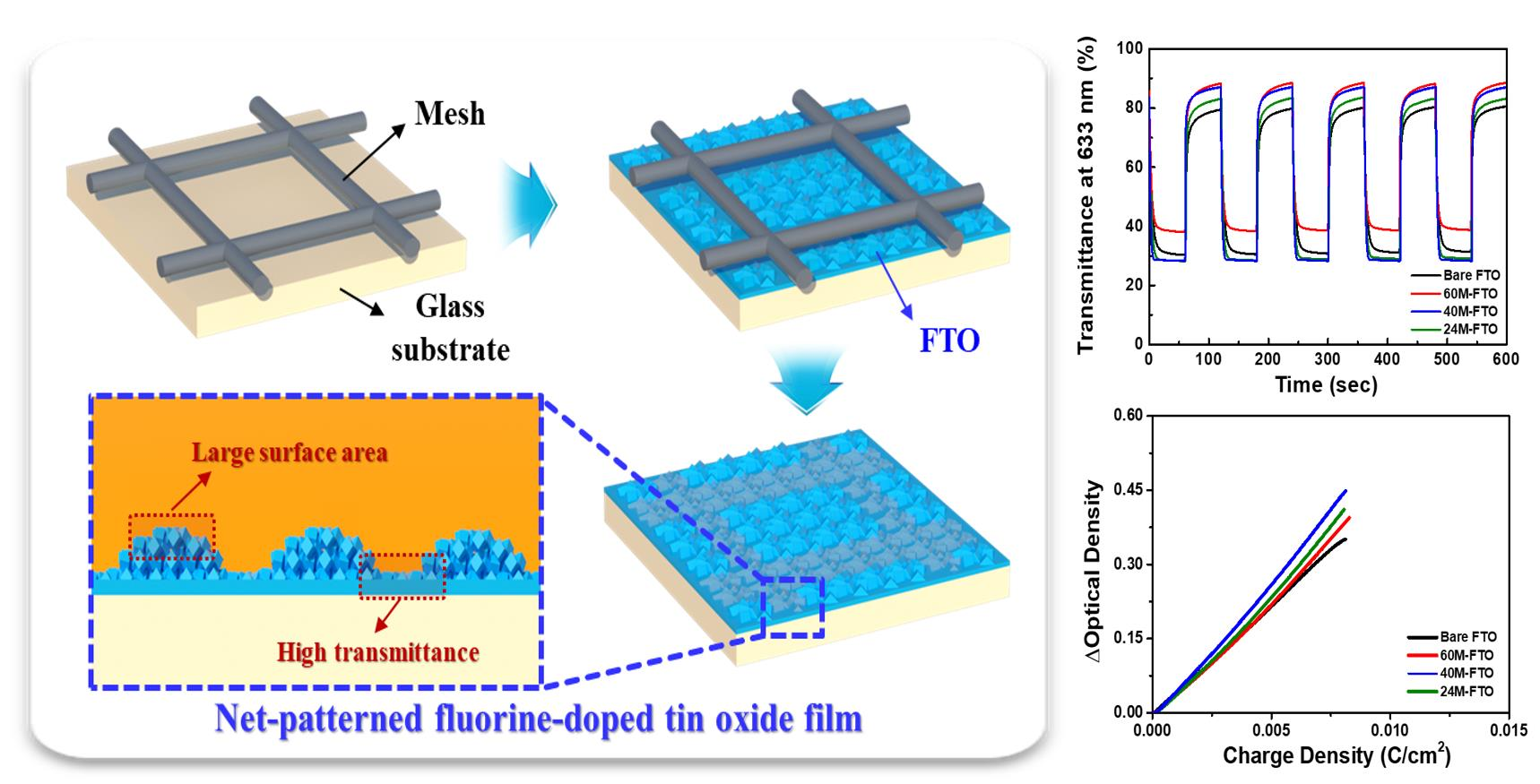

And catalytic Pt films for dye-sensitized solar cell DSC module. Three-dimensional macroporous fluorine-doped tin oxide p-FTO films were successfully deposited using commercial ink of FTO powder and SnCl 2 salt via Dr. The preferred liquid coating composition includes the reaction.

Fluorine atoms resulting from the decomposition of SF 6 seem to cause both etching of the tin oxide films decrease of the thickness probably in the form of Sn O F bondings as well as a functionalization of the surface forming either Sn F andor C F bondings. Ω and average visible light transmittance exceeded 80. Various dimensions are available.

Please request a quote above to receive pricing information based on your specifications. Fluorine-doped tin oxides for mid-infrared plasmonics Farnood Khalilzadeh-Rezaie1 Isaiah O. Large area 15 x 15 cm.

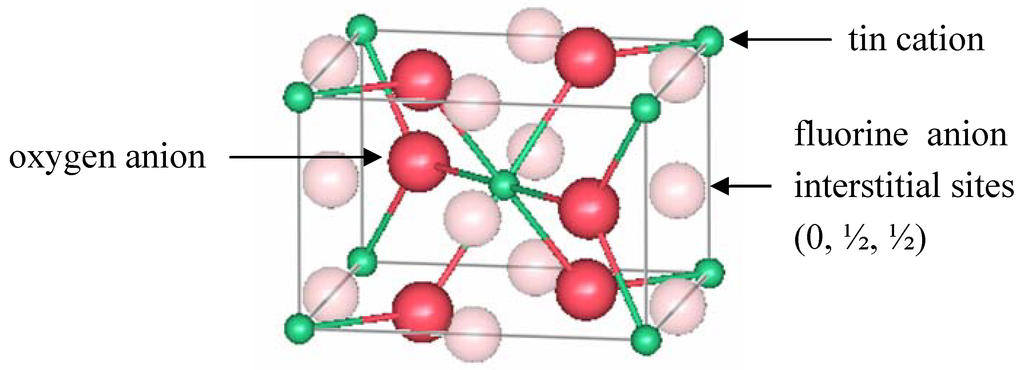

Related fluorine-doped zinc tin oxide FZTO thin films with higher zinc concentration from 55 to 355 atom and lower fluorine content 062 to 349 atom made by spray pyrolysis showing high transparency and bandgap values between 386 and 445 eV have also been reported. Its decomposition and the actual incorporation of fluorine in the tin oxide matrix were confirmed by X-ray photoelectron spectroscopy while its effect on the electrical properties was investigated by resistance and Hall measurements. TinIV oxide also known as stannic oxide is the inorganic compound with the formula SnO 2The mineral form of SnO 2 is called cassiterite and this is the main ore of tin.

With many other names this oxide of tin is an important material in tin chemistry. Fluorine-doped tin oxide FTO electrodes have been investigated for use instead of indium-doped tin oxide ITO as the holeinjecting electrode in polymer light-emitting diodes LEDs. Fluorine doped tin oxide thin films were successfully deposited onto well cleared glass substrate at different deposition parameters.

Three FCS species ie PVdF Aldrich PTFE Aldrich or PFOA Aldrich were used. 1 a the first decomposition observed at 400 C is attributed to the decomposition of Zn OHF to form ZnO and ZnF 2. Spray pyrolysis deposition SPD technique has been employed to prepare large area fluorine-doped tin oxide FTO nanocrystalline TiO.

Various features of p-FTO thin films were studied as a function of the ink composition and sintering temperature. The XRD patterns of the films showed that the deposited films are polycrystalline in nature having the characteristic peaks of tetragonal structure of SnO 2The peaks observed are. Of the fluorine dopant and 70-99 wt.

In the TGA of aqueous ZnF 2 solution Fig. For this purpose un-doped and fluorine-doped tin-oxide SnO 2 thin films were prepared by sol-gel dip coating process. A method for forming a fluorine-containing tin oxide coating on the surface of a substrate which comprises contacting the heated surface of the substrate with a vapor of monobutyltin trichloride or a mixed vapor of monobutyltin trichloride and a doping agent composed of a fluorine-containing compound of the following formula XCHFsub2 wherein X represents a fluorine atom a chlorine atom or.

The effects of fluorine doping rate SnO 2 films properties are studied. The XRD patterns of the films showed that the deposited films are polycrystalline in nature having the characteristic peaks. Fluorine-doped tin oxide films were deposited on silicon glass and quartz substrates at 370490C by atmospheric-pressure chemical vapor deposition from CH 3 CH 2 3 2 SnO 2 CCF 3 2 and oxygen.

The synthesis of f luorine doped tin oxide thin films were successfully deposited onto well cleared glass substrate by varying the deposition temperature. In the present work undoped SnO 2 and fluorine-doped tin oxide FTO thin films were prepared by sol-gel process using a solution composed of SnCl 2 H 2 O NH 4 F and ethanol mixture. Of the organotin compound.

The fluorine concentration effect on structural optical and electrical properties of SnO 2 films is investigated. A laboratory-sized planetary mill Pulverisette 7 Premium line. We describe the production of pure and fluorine-doped tin oxide by thermal decomposition and oxidation of precursors for tin and fluorine in the gas phase.

Industrial experience with tin oxide has shown that CVD at atmospheric 4ressure is the most cost-effective method for its production. Increasing the fluorine content in the film beyond 53 at resulted in a degradation of the electrical properties. Cleary3 Nima Nader34 Janardan Nath1 Imen Rezadad1 and Robert E.

Backscattering spectra indicate the films are stoichiometric with OSn ratios of 1920. This is probably attributed to the solubility limit of fluorine into the tin oxide lattice 11 and probably the cause for the reduction in the grain size as observed in Table 3 3. The initial results presented here lead to the conclusion that the electrodepolymer interface is much more complex than a simple energy level diagram might imply.

The morphological studies corroborated formation of porous uniform and crack-free FTO films after. The electrical properties of FTO films prepared by sol gel remain relatively lower than the. The transparent conducting FTO film gave low sheet resistance 8.

In the present work undoped SnO2 and fluorine-doped tin oxide FTO thin films were prepared by sol-gel process using a solution composed of SnCl2 H2O NH4F and. Peale1 1Department of Physics University of Central Florida Orlando FL 32816 USA 2SISOM Thin Films LLC Orlando FL 32805 USA 3Air Force Research Laboratory Sensors Directorate Wright-Patterson Air Force.

Materials Free Full Text Investigating The Defect Structures In Transparent Conducting Oxides Using X Ray And Neutron Scattering Techniques Html

Solution Processed Flexible Fluorine Doped Indium Zinc Oxide Thin Film Transistors Fabricated On Plastic Film At Low Temperature Scientific Reports

Catalysts Free Full Text Net Patterned Fluorine Doped Tin Oxide To Accelerate The Electrochromic And Photocatalytic Interface Reactions Html

Xps Survey Spectrum Of The Surface Layer Of Fto Films Tempered At Download Scientific Diagram

Sulphate Radical Enhanced Photoelectrochemical Degradation Of Sulfamethoxazole On A Fluorine Doped Tin Oxide Copper I Oxide Photoanode Sciencedirect

Tidak ada komentar