This paper reports the controlled micromachining of 100 nm thick indium tin oxide ITO thin films on glass substrates with a vacuum-ultraviolet 157 nm F 2 laser. Then place two probes on the copper foil and get reading for the sheet resistance.

Indium Tin Oxide Ito Glass For Research And Production

ITO was deposited via rf-magnetron sputtering using a 3-in diameter target of 10 Indium oxide 90 Tin oxide.

How can you cut indium tin oxide substrate. Since ITO is a transparent conductor it. Methods are described for etching patterns in conducting indium-tin oxide films on glass substrates. Therefore ITO films are usually sprayed on glass plastic and electronic display screens used as a transparent conductive film while reducing the harmful electronic radiation ultraviolet and infrared.

Chlorinated indium tin oxide electrodes with high work function for organic device compatibility. The sputtering was carried out at room temperature with an rf power of 125 W and a DC bias on the platen under these conditions of 3040 VThe bandgap was measured of these as-deposited sample without further annealing to be 35 eV by fitting the leading edge of the energy loss. The electrical and mechanical properties in indiumtinoxide films deposited on polymer substrate were examined.

Previous article Next article. The ITO layer can be prepared by standard sputtering techniques onto a glass plate or a plastic substrate. Please let us know if any interest you.

Parylene was applied as an ultra-flexible substrate through chemical vapor deposition. 10 ohmsq ITO coated SiO2 wafer Surface. 31 May 2011 Nanophotonics.

Maskless laser patterning of indium tin oxide ITO thin films was studied by the use of a diode-pumped Q-switched NdYLF laser. Cut ITO thin film in a square shape and coat the copper foil on upward and down side of the ITO film. In most cases a thin film of indium tin oxide ITO with a thickness in the order of 01 mm is used as the anode ma-terial.

10 6590 each 25 5590 each 50 4790 each 100 4300 each----. The use of a shutters system. The laser wavelength was.

We have the following Indium Tin Oxide wafers. Indium Tin Oxide films are inherently brittle in nature. Indium tin oxide ITO on polyethylene terephthalate PET substrate is characterised in terms of pH-sensitivity.

As a nano indium tin metal oxide ITO has excellent electrical conductivity and transparency and can cut off electron radiation ultraviolet rays and far infrared rays harmful to the human body. The ITO films were sputter-deposited either on lime glass the standard substrate material for flat panel display applications or fused quartz so that the efficiency of laser patterning as a function of substrate absorption could be studied. The total refractive index of our indium tin oxide-coated glass is unspecified.

So the second harmonic generation is obtained from the fundamental beam and the angle variation of the crystal allows us to operate by the ratio of the powers in the two channels. Or if you know of better pricing elsewhere. The distance between two probes of multimeter should be 1 cm and placed the probe at an angle of 45 degrees to the surface so that you can get the.

ITO can be easily deposited on soda lime glass substrates as a high-quality thin film and the industry has decades of experience with this material set. The coating is highly transparent to allow application on glass for various purposes. You can find the glass substrates refractive index in the respective substrate glass specifications see links above.

Of 45 degree to the surface so that you can get the exact resistivity of the substrate. Solution vapors can irritate mucous membranes and can cause burns and should be avoided. Optical microscopy atomic force microscopy and energy dispersive.

Commercial ITOPET sheet was cut in a shape of electrode and was connected to the gate-terminal of a metaloxidesemiconductor field-effect transistor as the sensory part creating an extended gate field-effect transistor EGFET pH-sensor. The objective of this study is to investigate the effect of long-term static bending on the conductive characteristics of indium tin oxide ITO thin film in flexible optoelectronics. Finally see letter 40228 for a third approach.

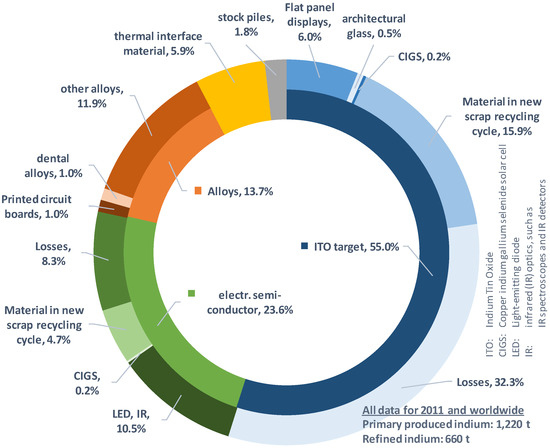

Depending on the oxygen content it can either be described as a ceramic or alloyIndium tin oxide is typically encountered as an oxygen-saturated composition with a formulation of 74 In 18 O 2 and 8 Sn by weightOxygen-saturated compositions are so typical that unsaturated compositions are. The sputtering target composed of 70 at. Indium tin oxide coated polyethylene terephthalate PET film is optically transparent and electrically conductive.

Following the immersion cycle the substrates should be removed and rinsed several times with deionized water and finally blown dry with a clean oil-free nitrogen or air source to avoid water spotting. If you would like to know more about our Indium Tin Oxide coated glass or any of our other ITO and anti-reflective products please get in touch with us. Apart from glass this coating is applied to other materials including plastics polyester thin-film acrylics and polycarbonates.

Ted Mooney PE. Indium tin oxide substrate. Light-emitting indium tin oxide.

Indium tin oxide ITO is a ternary composition of indium tin and oxygen in varying proportions. Partial to complete film removal was observed over a wide fluence window from 049 Jcm 2 to an optimized single pulse fluence of 45 Jcm 2 for complete film removal. For patterns requiring maximum definition and resolution hydriodic acid is preferred whereas hydrofluoric acid or zinc and hydrochloric acid are useful for other purposes.

Science 332 944947 doi. The materials of substrates were polyethersulfone PES which have gas barrier layer and antiglare coating for plasticbased devices. Another technology you might look into is ITO indium tin oxide -- the stuff they use to make LCDs.

Indium tin oxide is an oxide with conduction properties coated on various substrates including glass. To overcome this ITO is coated with transparent conductive polymers or nanomaterial. We would be happy to assist with any enquiry.

Indium-zinc-tin oxide IZTO thin film was used as a transparent electrode. The ITO coating is protected by a thin transparent film that can be easily peeled off. Two types of substrate are considered namely ITO on polyethylene naphthalate ITOPEN and ITO on polyethylene terephthalate ITOPET.

We have developed a novel structure of ultra-flexible organic photovoltaics UFOPVs for application as a power source for wearable devices with excellent biocompatibility and flexibility. Indium tin oxide coated glass is probably the most popular substrate for systems that need the conductivity and transparency provided by TCOs. The refractive index of transparent indium tin oxide films remains around 195 for.

Light-emitting indium tin oxide Download PDF. Cut under the angle of phase-matching conditions. Electrical properties of the ITOPEN and ITOPET sheets are measured in.

Indium Tin Oxide In Chemistry Stanford Advanced Materials

Extraction Of Indium Tin Oxide From End Of Life Lcd Panels Using Ultrasound Assisted Acid Leaching Sciencedirect

Indium Tin Oxide Obtained By High Pressure Sputtering For Emerging Selective Contacts In Photovoltaic Cells Sciencedirect

Pdf Indium Tin Oxide Ito Serpentine Ribbons On Soft Substrates Stretched Beyond 100 Semantic Scholar

Electrochemical Impedance Spectra For Indium Tin Oxide Ito Electrodes Download Scientific Diagram

Tidak ada komentar