Physical and Mechanical Properties of Solder Alloys. Fine Silver 9999 105.

A Comparison Of Tin Silver Copper Lead Free Alloys Aim Solder

Several variations of this alloy are available but the conductivity for all of them is approximately 60 WmK at 25C.

Electrical conductivity and resistivity of tin silver copper solder alloy. It is therefore expected that thermal conductivity and electrical resistivity are related by the Wiedemann-Franz law 8. Experimental Sn-Ag-Cu Solder Alloys. Material Conductivity mhom Resistivity ohm-m Source TiC 017 107 1 TiN 11 10 8 1310 7 4 TiO 2 1011 5 WC 5 107 5 WSi 2 334 108 549 108 4 ZrB 2 92 108 4 ZrC 61 108 64108 4 ZrO 23Y 2O 3 1010 2 ZrO2 monoclinic 1011 5 POLYMERS Material Conductivity mhom Resistivity ohm-m Source Polymethylmethacrylate.

Tin itself has a very low melting point tin. It has higher electrical conductivity than other soft solders and a melting point approximately 40C higher than either 6040 6337 or LMP alloys. Electrical resistivity and its converse electrical conductivity.

In Table 1 the thermal conductivity which is the product of the measured thermal diffusivity density and heat capacity is listed as 0342 - 0051 wattcmdeg for Cu 6 Sn 5 0698 - 0098 for Cu 3 Sn and 0196 - 0019 for Ni 3 Sn 4. C17530 Beryllium Copper IACS of Solder Alloys Calculation based on Resistivity Normallized to Copper IACS Calculation based on Resistivity Normallized to Copper IACS of Pure Metals Alloy C17500 Beryllium Copper Alloy. Electrical resistivity represented by the Greek letter ρ rho is a measure of how strongly a material opposes the flow of electric current.

Assume 12 AWG copper wire with a resistivity from the table of 172x10-6 Ωcm a. For electrical soldering which I do alot of I do exclusively use the 2 silver bearing solder. Tin has long been used in alloys with lead as solder.

In comparison metals like aluminum have only 61 percent of the conductivity of copper. Tin has long been used in alloys with lead as solder. This table presents the electrical resistivity and electrical conductivity of several materials.

Pure Copper Tin and Nickel and Their Intermetallics. It is generally 11-13 the conductivity of copper. Tin resists corrosion making it an ideal coating for other metals.

Electrical resistivity of Silver is 159 nΩm. The surest way to find the conductivity is to just look in the data sheet for that vendors SAC305 alloy. If flows easier cleaner and will have some conductivity superiority over the ol 6040 stuff.

Conductors are made of high-conductivity materials such as metals in particular copper and aluminium. Electrical resistivity is inverse to electrical conductivity. Pure copper has the best electrical and thermal conductivity of any commercial metal.

Like pure tin it is bright hardly tarnishes is lead-free and non-toxic but unlike pure tin it is relatively strong. Due to its much lower cost and greater abundance copper has traditionally been the standard material used for electricity transmission applications. SAC305 isnt standardized there can be some variation in the alloy and it really comes down to the manufacturer.

A 1039E-07 9628E06 1660 1 Silver Tin Solder 1039E-07 9628E06 1660 1 Tin Silver Solder 1039E-07 9628E06 1660 1 Solder Tin Silver 1059E-07 9442E06 1628 1 Platinum 1078E-07 9280E06 1600 1 Palladium 1105E-07 9048E06 1560 1 Iron Ignot 999 Fe 1105E-07 9048E06 1560 1 Ingot Iron 999 Fe 1149E-07 8700E06 1500 1 Tin Pure 1149E-07 8700E06 1500 1. Tin is one of the first metals known to humans it is nontoxic soft and pliable and suitable for cold rolling. Electrical Conductivity IACS 120 Electrical Resistivity Microhm-cm NA Bulk Room Temperature Tensile Strength PSI 6900 IACS International Annealed Copper Standard SOLDERING CHARACTERISTICS This alloy is considered to be a high strength solder.

Electrical resistivity and thermal conductivity are evaluated usually at 20C and 85C respectively. Substances in which electricity can flow are called conductors. TinSilverCopper alloys have much higher creep strengths than the standard tinlead solders.

Tin is one of the first metals known to humans it is nontoxic soft and pliable and suitable for cold rolling. 238 rows conductivity converted from resistivity Solder Antimonial Tin. Tin has a low coefficient of friction and the addition of alloying elements such as copper antimony bismuth cadmium and silver increase its hardness.

96S TINSILVER SOLDER Multicore 96S alloy is the pure tinsilver eutectic alloy. Tin has a low coefficient of friction and the addition of alloying elements such as copper antimony bismuth cadmium and silver increase its hardness. Tin resists corrosion making it an ideal coating for other metals.

1190 6902E06 1449E-07. Apart from silver copper is the best conductor of electricity. I bought a 1 pound roll off of ebay years ago for a about 20 and Im no where near 14 way through it yet.

Copper has a 100 percent conductivity rating and due to modern technological advances can even reach 101 percent conductivity compared to its own standard when oxygen is removed. Melting Point C solidus liquidus. Conductors Semiconductors Resistors.

Tin itself has a very low melting point tin. SAC387 reference alloy and SAC387 100x Co x alloys with x 053 wt were synthesized from silver casting grains 999 metallic purity Alfa Aesar Karlsruhe Germany tin ingot 99998 metallic purity Alfa Aesar Karlsruhe Germany copper rods 999 metallic purity Alfa Aesar Karlsruhe Germany and cobalt chucks 999 metallic purity Alfa Aesar Karlsruhe Germany. 11 rows Electrical Conductivity IACS Electrical Resistivity ucm.

Electrical conductivity is often expressed in IACS which stands for International Annealed Copper Standard. Physical and Mechanical Properties of Lead-Free Alloys and Sn-37Pb eutectic Table 119. A candidate to replace tin-lead SnPb solder is an alloy of tin Sn silver Ag and copper Cu termed SAC.

Silver Electrical Resistivity and Electrical Conductivity. Several copper alloys now exceed 100 and 101 IACS Typical soldering wire alloys listed in order of melt temperature. Room-Temperature Physical and Thermal Properties.

80 rows Solder Alloy. Effects of Transition Metals on Vickers Hardness and Ultimate Tensile Strength of Sn-4. The lower the resistivity the more readily the material permits the flow of electric charge.

The conductivity of copper is 97 that of silver.

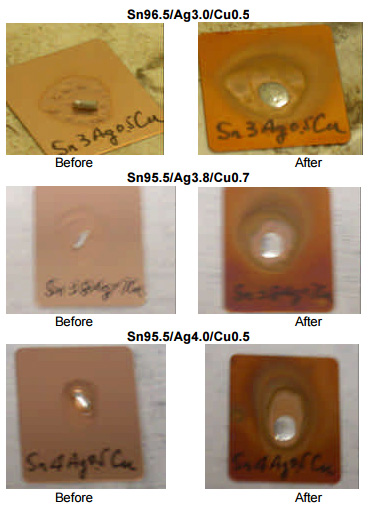

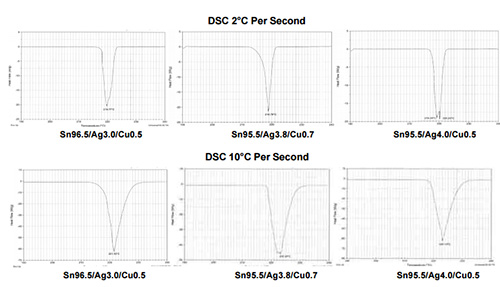

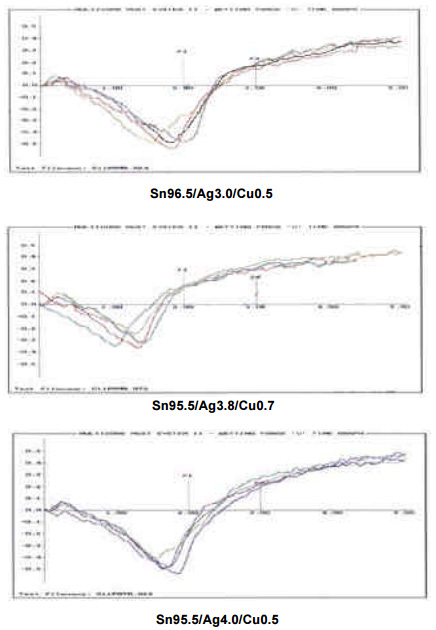

A Comparison Of Tin Silver Copper Lead Free Alloys Aim Solder

How Strong Is Silver Solder Really Welding Mastermind

A Comparison Of Tin Silver Copper Lead Free Alloys Aim Solder

How To Correctly Braze Silver Solder A Copper Pipe 5 Steps With Pictures Instructables

Tidak ada komentar